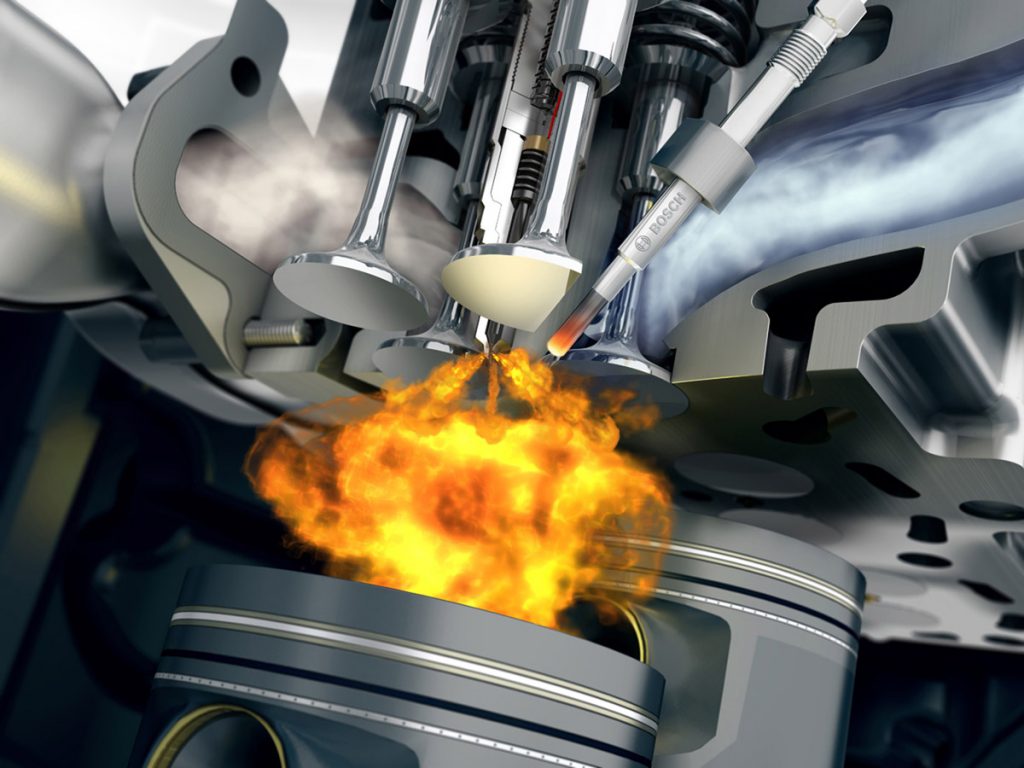

A diesel engine works by compressing a combination of fuel and air, resulting in combustion. Diesel engines don’t rely on a spark-ignited system to combust the fuel/air mixture. When combustion occurs, the energy released allows the car to move.

The remnants of the air/fuel mixture that ignited are eventually moved from the combustion chamber to the tailpipe where they are ejected from the vehicle. The exhaust system is responsible for playing this role. It ensures that the waste produced by the combustion process is eliminated from the car. This is what you should know about the way it works:

1). When combustion occurs, the exhaust gases produced move from the exhaust ports of the engine cylinders to the manifold.

The manifold is connected to the exhaust system. This allows the gases in the manifold to eventually transition through the various components of the exhaust system before reaching the tailpipe.

2). The exhaust system consists of decoupling elements, pipes and hangers, mufflers, and after-treatment devices.

3). The muffler is basically soundproofing.

It reduces the noise generated by the engine by dampening the vibrations it produces. In some places, the muffler is also called a silencer. The muffler is part of the cold end of the diesel system along with the tailpipes.

4). The decoupling elements connect the exhaust system and the manifold.

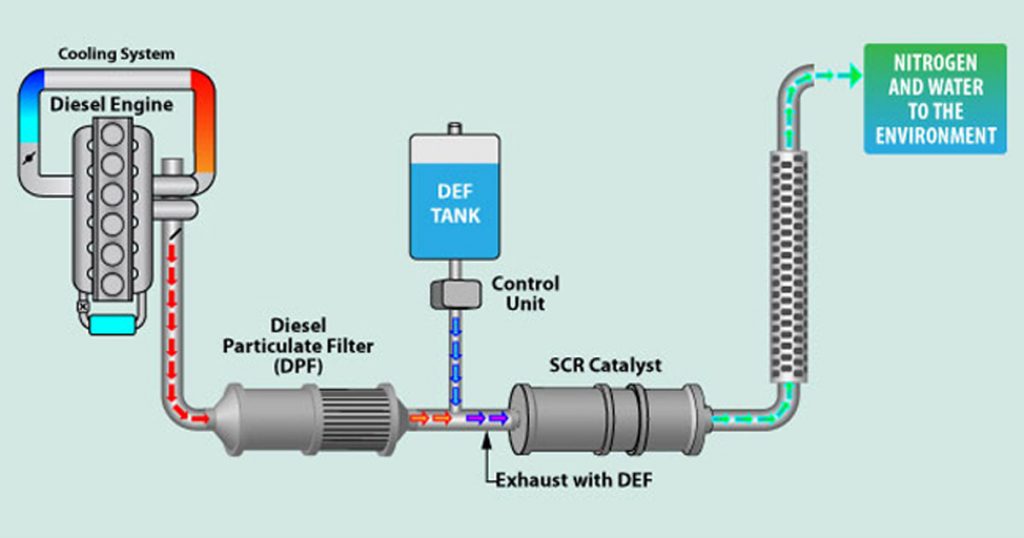

5). The after-treatment system hasn’t always been present in the configuration of the diesel engine.

For a while, the exhaust system was simply tasked with taking exhaust gas from the combustion chamber and depositing it in the environment.

But after a while, experts realized that these gases possessed harmful components that could negatively impact the environment. As a result, various authorities introduced laws that were designed to regulate the emissions produced by vehicles.

Manufacturers were charged with creating tools that could treat the exhaust gas after it left the engine to make it safer for the environment. This led to the invention of after-treatment systems.

6). One of the most important pollutants generated by diesel engines is particulate matter.

This is fuel and diesel fluid that wasn’t completely burned in the combustion chamber. When it is ejected through the tailpipe, particulate matter manifests as black smoke.

7). One of the most critical components of an after-treatment system is a catalytic converter that turns carbon monoxide into carbon dioxide and hydrocarbons into water and carbon dioxide using various chemical reactions.

The best catalytic converters are supposed to eliminate the smell of diesel, not to mention soot.

8). Besides the catalytic converter, after treatment systems also make use of particulate filters.

The filters tackle the visible particles that the catalytic converter fails to capture.

9). Modern systems have a diesel oxidation catalyst which turns accumulated soot into ash using extreme heat.

The ash remains in the particulate filter.

10). Some vehicles have systems that use the gases from a combustion chamber for braking purposes.

These vehicles still possess wheel brakes. However, the gases from the combustion chamber use a special brake that eases the burden the wheel brakes normally carry. A perfect example of this is the Flo Pro Exhaust system.